A pin insulator is a protective device for electrical cables. It is a strong cylinder or cone made from materials like porcelain, glass, or certain polymers. It is also called a porcelain insulator or a polymer pin insulator. A metal pin extends from one or both ends of the insulator.

The insulator pin is attached to a pole-like structure, typically made of a wooden beam, called a utility pole. At the other end of the insulator, the wire is connected. This setup prevents electricity from flowing from the wire to the pole, ensuring safety.

Pin insulators are mostly used in overhead lines. They can withstand strong winds, rain, and air pollutants and bear the heavy weight of the wires, providing additional support to the electrical system.

Read More About Electrical Engineering

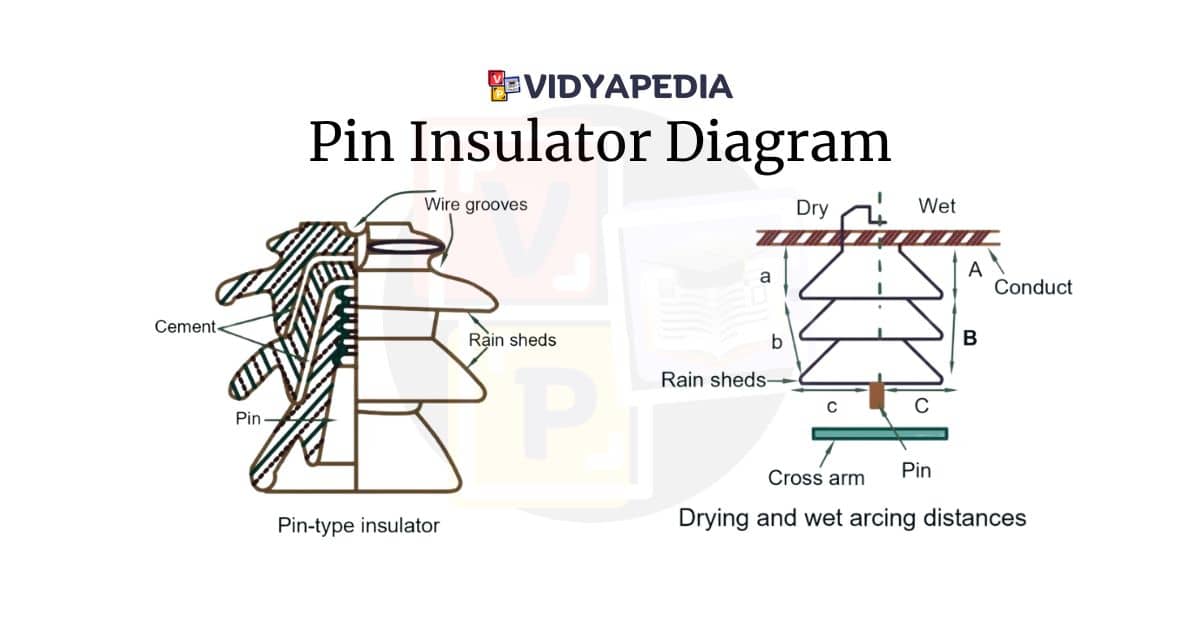

Pin Insulator Diagram

Wire Grooves: It has grooves that hold the wire in place securely. They’re like little holders that keep everything stable, so the wire doesn’t move around too much.

Cement is used to stick the metal pin very tightly. This makes the insulator stable when there is a windy environment.

Metal pin: it is a very important part of the insulator and is used for making connections or supports between pole and wire. It’s usually made of tough materials like steel, so it can handle the wires without breaking.

Rain Sheds: The insulator is the topmost part of the setup, used to prevent rain from getting inside and affecting the surface of the insulator. It ensures that the current will not flow from the pole to the wire while raining, protecting the system and preventing damage. It also protects from dust.

Cross arm: It is used to provide support to the pole and wire. It is made up of durable material to provide stability to the conducting wire in between the poles.

Conductor: it makes the connection complete.

Dry part: it always remains protected from rain and any moisture, which makes the system insulated from any weather conditions.

Wet part: It is exposed to external environments like rain and snow and designed to withstand moisture without losing its functionality.

220V or 440V Pin insulation

For low voltage (220V and 440V):

For low-voltage applications like 220V and 440V systems, a single-piece pin insulator suffices. It provides adequate insulation to prevent electrical leakage and maintain system reliability.

11KV Pin Insulator

For medium voltage (11 kV):

In medium-voltage setups, such as 11 kV systems, pin insulators often comprise two or more pieces cemented together. This construction ensures the proper thickness of the insulator, enhancing its ability to withstand higher voltages.

33Kv Pin Insulator

For high voltage (33 kV and above):

High-voltage configurations, like those operating at 33 kV and higher, require multiple pieces of pin insulators cemented together. This design is crucial for maintaining sufficient insulation thickness and providing a reliable path for leakage current.

Regarding flashover voltage, it’s important to note that surfaces with moisture and dirt have a lower flashover voltage compared to clean and dry surfaces. Regular maintenance to keep insulators clean is essential for optimal performance and safety.

Understanding the total dry and wet arcing distances is also vital. The dry arcing distance, denoted as (a+b+c), represents the sum of direct distances through the air. Conversely, the wet arcing distance, represented as (A+B+C), considers the impact of moisture on arcing distances.

These considerations are fundamental in designing and maintaining electrical systems across different voltage levels, ensuring efficient power transmission, and minimizing the risk of electrical faults.

Differences between 11 kV pin insulators and 33 kV pin insulators

| Aspect | 11kV Pin Insulator | 33kV Pin Insulator |

|---|---|---|

| Voltage Handling Capacity | Designed for medium voltage, around 11,000 volts | Built for higher voltages, around 33,000 volts |

| Insulator Construction | May consist of multiple pieces cemented together | Typically constructed with more pieces and complex assembly processes |

| Physical Dimensions | Smaller and lighter compared to 33kV insulators | Larger and heavier due to higher voltage rating |

| Application Areas | Commonly used in distribution networks and medium-voltage transmission lines | Primarily employed in high-voltage transmission lines and substations |

Frequently Asked Question

What is a pin insulator’s role?

It protects electrical cables by isolating them from structures like poles or utility beams.

How do dry and wet arcing distances impact pin insulators?

Dry distance is the direct air path, wet distance considers moisture’s effect, both crucial for efficient electrical systems.

What affects flashover voltage in pin insulators?

Moisture and dirt lower flashover voltages, emphasizing the need for regular cleaning.

How are pin insulators attached?

The metal pin attaches to a structure, while the electrical wire connects to the other end of the insulator.

What are the main components of a pin insulator?

Wire grooves secure the wire, cement fixes the pin, and rain sheds prevent water damage.

What’s the difference between low, medium, and high-voltage pin insulators?

Low voltage uses single-piece insulators; medium voltage uses multiple pieces; and high voltage requires more insulation layers.

What are the differences between 11 kV and 33 kV pin insulators?

11kV are smaller for medium voltage, while 33kV are larger for high voltage systems